Key outcomes from Cleanaway’s demonstration:

- HVO100 renewable diesel provided equivalent or better fuel consumption, uptime and performance compared to mineral diesel oil in two Cleanaway heavy vehicles and has avoided 37 t CO2 of emissions so far

- Cleanaway’s customers, employees, and industry recognise the benefits of this renewable fuel and would like to see a roll out of low carbon liquid fuels at larger scale

- Policies to support the uptake of low carbon liquid fuels have been announced by the federal government, which will be essential to driving increased market penetration

Since February 2024, we have been supplying Cleanaway with HVO100 renewable diesel to power two heavy vehicles from their Perry Road depot. This demonstration seeks to show that HVO100 can be a scalable, sustainable alternative to traditional fossil fuels. This initiative is a testament to our commitment to provide industry with innovative, sustainable solutions and aligns with Cleanaway’s Blueprint 2030 strategy to provide high circularity, low carbon solutions.

The fuel used in this demonstration is Hydrotreated Vegetable Oil (HVO), a renewable diesel that is a drop-in alternative to traditional diesel and is made from renewable, waste resources such as used cooking oil. It can reduce greenhouse gas emissions from vehicles by up to 90 per cent.

For Cleanaway, the objective of the demonstration is to collect data on how vehicles that pull a payload of between seven to nine tonnes for 12+ hour per day perform on this alternative fuel, and whether it could be a scalable replacement for traditional fossil fuels to decarbonise their fleet.

Cleanaway CEO Mark Schubert said, “The use of HVO100 in Cleanaway trucks is part of our Blueprint 2030 strategy to reduce the carbon impact of our operations and increase circularity from the material we collect.

“We're committed to leading our industry with innovative and fit for purpose solutions that align with our customers‘ goals while working towards federal emissions targets.”

The Neste MY renewable diesel supplied by Viva Energy and used in this demonstration, is exclusively attributed to used cooking oil feedstock and reduces greenhouse gas emissions by approximately 91% compared to landed fossil fuel across the lifecycle including extraction, transport, conversion and combustion. Neste is committed to 100% sustainably sourced renewable raw materials with a fully traceable supply chain to ensure trust and credibility, which supports Cleanaway’s commitment to high circularity, low carbon sustainable solutions.

What is HVO100?

HVO100 renewable diesel is hydrotreated vegetable oil made from waste sources like vegetable oils and animal fats. It is manufactured from a process called “Hydrotreatment” using hydrogen and catalysts at high temperatures and pressures.

With a chemical composition similar to petroleum-derived diesel, HVO is a lower emissions alternative to traditional diesel. And, as a drop-in replacement for diesel, it seamlessly integrates into existing machinery and storage tanks and requires no new supply chain infrastructure, fleet, or additional capital.

Since the demonstration started in February, Cleanaway has collected data on their fleet’s performance, the impact on supply chain and operations, and their cost model. These insights can help inform how governments, industry and other heavy vehicle operators can approach decarbonisation.

Cleanaway vehicle next to HVO100 renewable diesel tank at Perry Road depot. Livery reads “This truck is powered by used cooking oil”.

Fuel consumption and emissions

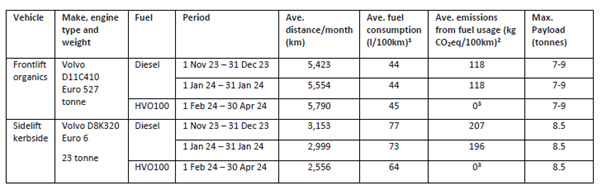

Fuel consumption of both vehicles is summarised in the table below. For their frontlift organics truck, Cleanaway observed a very similar performance between diesel and HVO100. In their truck, which has, on average, a much higher fuel consumption due to more frequent stopping, they observed a lower consumption using HVO100.

The fuel consumption figures were confirmed by feedback from Cleanaway’s drivers. For the frontlift organics truck, the driver did not notice any difference in refuelling frequency or power delivery. However, the sidelift truck driver noticed that the intervals between his refuelling were longer since the HVO100 demonstration began, indicating that he achieved more mileage from a full tank. This observation confirmed the fuel consumption data.

Cleanaway noted that it is not yet clear what causes this lower consumption and why it was only observed in the sidelift vehicle. Cleanaway will monitor how this evolves throughout the demonstration.

1 Excluding idle time. 2 Based on emissions factors from NGERs determination 2008. 3 There are very small residual methane and nitrous oxide emissions when HVO100 is combusted. However, these are omitted here due to their immaterial contributions.

Exhaust gases were analysed using a gas analyser to measure CO and CO2 concentrations from the exhaust pipe. Measurements on the sidelift truck showed equivalent results between HVO100 and diesel when idle and at 1,500 rpm. HVO100 is approved as a reportable emissions reduction solution by the National Greenhouse and Energy Reporting Scheme (NGERS) and has negligible emissions from combustion as it is derived from renewable raw materials that have sequestered CO2 from the atmosphere when the biomass was grown. Based on the consumption figures in the table, the HVO100 demonstration has avoided a total of 37 t CO2 in the first three months of the demonstration across both trucks.

From a maintenance perspective, a fuel filter was extracted three months into the demonstration and it was noticeably cleaner compared to used filters from trucks running on mineral diesel.

Customer experience

Uptime and performance is essential for servicing Cleanaway’s customers.

Coles is one of two Cleanaway customers participating in the demonstration. “Our involvement in the trial of a Cleanaway truck powered by renewable fuel has been successful, with HVO100 currently completing 189 services per week across 72 of our stores in southeast Melbourne”, said Coles General Manager Sustainability, Brooke Donnelly. “This is an exciting opportunity to drive change in the industry and help to create a more sustainable future.”

Similarly, Cleanaway’s municipal customer, City of Casey, commented: “The City of Casey is proud to be part of Cleanaway's HVO100 demonstration - using a lower carbon, diesel alternative to power one of Casey's kerbside collection vehicles. We encourage our community to keep an eye out for the bright blue trucks operating on renewable fuel, attributed exclusively to used cooking oil. This emission reduction initiative is another step in the right direction in Council’s commitment towards zero net corporate emissions by 2030 in line with our Climate Action Plan."

Operations

The local team supporting the demonstration has embraced this innovative approach to reducing carbon emissions – especially once they saw how well the vehicles performed. Cleanaway’s demonstration requires a dedicated refuelling system which is a change to process for the drivers. This approach also required a bespoke supply chain solution, which was supported by Cleanaway’s fuelling partner, Viva Energy, and increased the cost per litre.

Cleanaway has noted that the cost of HVO100 could be a challenge for scaling the program as renewable diesel is not currently attracting the same subsidies as other fuel types.

Conclusion

Cleanaway is committed to incremental decarbonisation across its fleet and hope to lead the way for heavy vehicles across Australia by investing in new and emerging technologies. Cleanaway has purchased two green hydrogen trucks, anticipated to come online later in 2024 as part of Viva Energy’s new energy service station development in Geelong and also have a limited number of electric vehicles in the Cleanaway fleet. HVO100 is an opportunity to reduce emissions from the current fleet of 3500 operating on traditional diesel which have a 10-year lifespan.

Cleanaway’s provides important data and real-world experience for the development of a low carbon liquid fuels industry in Australia. Bioenergy Australia CEO Shahana McKenzie said: “This demonstration has been essential in moving the dial on low carbon liquid fuels with government, industry and businesses in Australia. Cleanaway is providing credible evidence to support policy, funding and build confidence for Australian businesses as they consider their decarbonisation pathways. Cleanaway is confident that this demonstration has had a positive impact on the Federal Governments recognition of low carbon liquid fuels in the 2024/2025 budget and Transport and Infrastructure Net Zero Consultation Roadmap”.